The Digitalization Trend Dominates the Traditional Furniture Manufacturing Industry

22.11.2024

The furniture manufacturing industry is facing significant pressure regarding productivity, quality, personalization, and cost. As the market undergoes challenging times, the key challenge for businesses is to reduce fixed costs while ensuring productivity meets increasingly complex demands. In this context, digital transformation, also known as digitalization, is no longer an option but an essential solution for survival, sustainability, and growth.

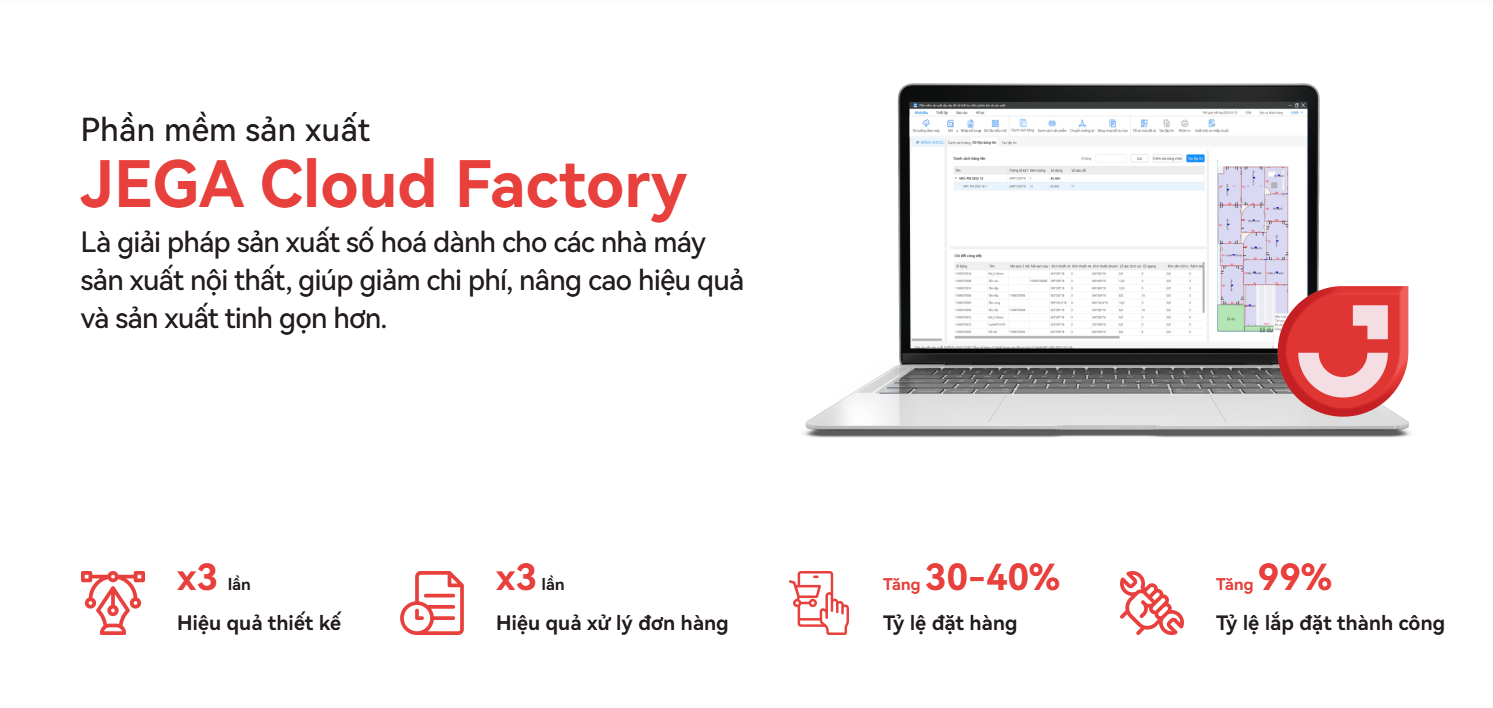

To promptly address the urgent demands of the market, JEGA has developed a comprehensive digital technology platform tailored specifically for the furniture design and manufacturing industry. JEGA connects all stakeholders, including architects, manufacturers, and suppliers of loose furniture, raw materials, and accessories, creating a robust collaborative ecosystem. Notably, the JEGA CLOUD FACTORY Lite software (JEGA Lite) serves as an all-in-one cloud-based production management solution, optimizing processes and enhancing efficiency for small and medium-sized manufacturing facilities.

This system seamlessly integrates stages such as design, production planning, material management, and progress tracking, enabling businesses to operate smoothly while reducing costs.

Let’s explore how JEGA Lite addresses current challenges and resolves industry pain points effectively.

Low Productivity and Efficiency

A production process that heavily relies on manual labor often results in low productivity and inefficiency. The JEGA Cloud Factory software, available in Lite and Pro versions, offers a solution for automating production processes. With features such as extracting design files, generating CAD files, and material lists with just one click; managing boards, streamlining workflows, and automatically scheduling production, the software minimizes human intervention, thereby improving production speed and enhancing the connectivity between stages.

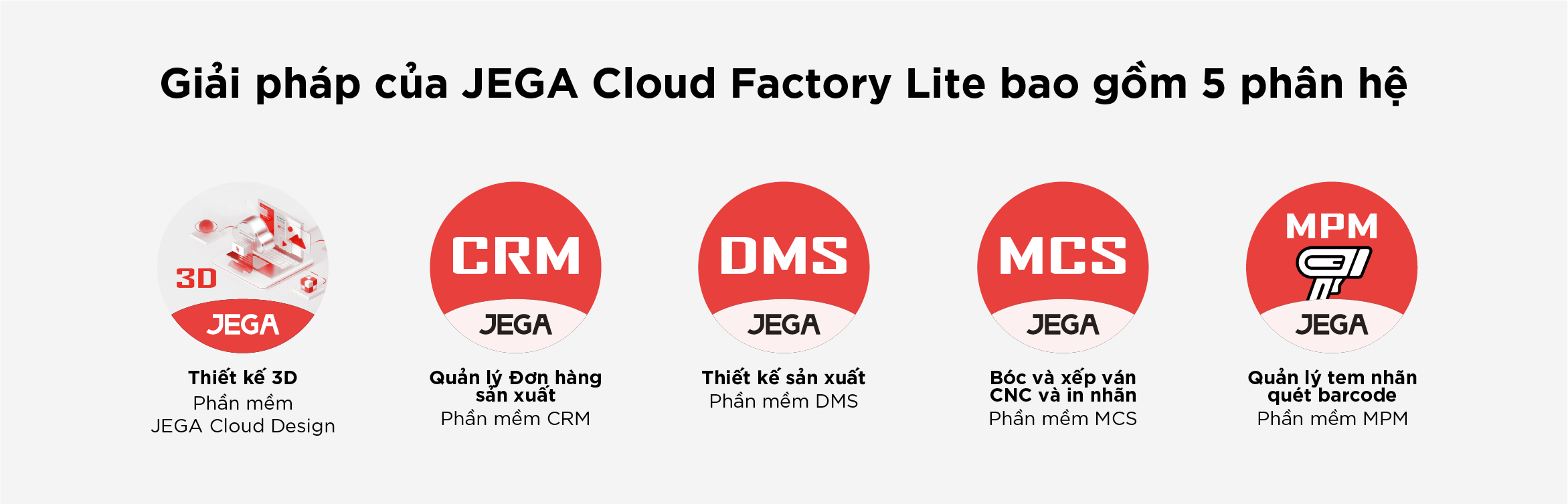

JEGA CLOUD FACTORY Lite comprises 5 key modules:

- 3D Design (JEGA Cloud Design): Create 3D drawings, automatically generate CAD files, quick quotations, and material lists.

- Production Order Management (CRM): Track order progress, customer details, and sales channels.

- Production Design, Inspection, and Automatic Order Breakdown (DMS): Create production design drawings, convert 3D design data into production data, automatically detect errors, and split cutting plans.

- Production Scheduling (MCS): Optimize board cutting, CNC operations, and labeling with up to 95% material utilization.

- Sorting and Packaging (MPM): Manage labels, scan barcodes, categorize, and organize packed items for delivery.

With JEGA Lite, manufacturing businesses not only fulfill internal orders but also produce furniture based on design drawings sent directly by architects using the JEGA Cloud Design software nationwide. Manufacturing businesses can provide accounts to partner architects, allowing them to log in and submit design orders directly to the factory. Through the CRM system, manufacturers can receive, process, and execute orders entirely online. Design drawings are seamlessly transferred within the system from the architects' JEGA Cloud Design platform to the manufacturers' JEGA Cloud Factory production management account.

Evidence shows that JEGA Lite significantly enhances productivity and efficiency. Previously, to create a curved detail, the production designer had to manually perform calculations, divide sections for grooving, and cut, which was a time-consuming process prone to errors. Now with JEGA Lite, the software automatically calculates and divides grooves for the CNC machine, reducing the time to just a few minutes while ensuring precision down to the millimeter. Furthermore, the software optimizes cutting paths, minimizing material waste compared to manual methods, contributing to lower production costs.

Weak Production and Procurement Management

Another significant challenge is the lack of connectivity and transparency between factories and suppliers of raw materials, accessories, and loose furniture. This issue results in delays in production and delivery, along with material losses, which negatively affect both profitability and the business's reputation.

To resolve this, JEGA’s comprehensive CRM system enables efficient order management, professional customer relationship management, and the optimization of sales channels. Furthermore, weaknesses in inventory management are resolved through the barcode system, which facilitates production management via barcodes, making it easy to check order statuses and trace product information.

Challenges in Understanding Market Demands

When manufacturing workshops focus solely on their technical expertise, market research, as well as updates on new materials and design trends, are often overlooked. This creates a significant gap in understanding and meeting the increasingly diverse needs of customers. Without tools to collect and analyze customer feedback, research and product development become challenging and, at times, inaccurate, leading to wasted time and effort. Consequently, this creates a competitive disadvantage compared to other products in the market.

JEGA Lite addresses this issue by enabling businesses to gather and process customer input effectively. By analyzing purchasing data to identify consumer trends, JEGA allows businesses to easily capture popular design styles, wood color codes, preferred wood panels, and accessories. This insight helps businesses make accurate predictions about market trends and adapt their offerings accordingly.

Shortage of High-Quality Human Resources & JEGA Lite’s Optimal Solution

JEGA Lite supports exporting CAD drawings, reading, and easily converting data from 3D designs into production data, quick quotations, and material lists, significantly reducing the workload for technical and production teams. This allows employees to develop and learn additional knowledge and skills to become more versatile.

Furthermore, JEGA Lite is designed with the principles of being easy to learn, easy to use, fully localized in Vietnamese and integrated with a library system that aligns with Vietnamese standards. This shortens training time, allowing employees to quickly familiarize themselves with and master the software, thereby improving work efficiency and minimizing errors.

Commenting on the benefits JEGA brings to factories, Mr. Nguyen Trong Son, Factory Manager at Flexfit, affirmed: "The new process with JEGA has significantly streamlined manual steps, automating everything from design, data extraction, and quotation to production, helping save time, reduce costs, and minimize errors."

|

JEGA - A Comprehensive Platform for the Furniture Industry. Address: 2nd Floor, National Exhibition Construction Center Contact for consultation on JEGA solutions: 035.904.6888 Website: https://jega.vn |